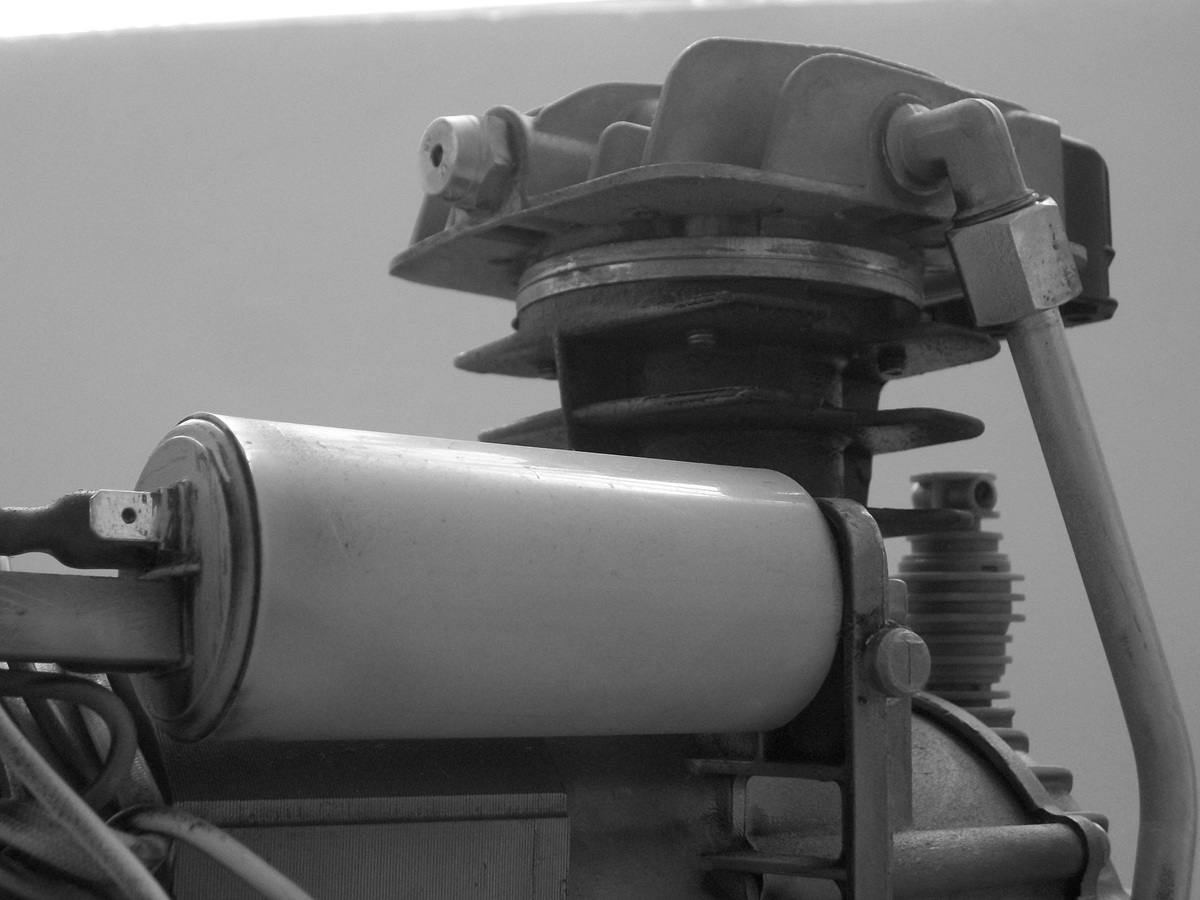

Air compressors are important pieces of equipment used in a variety of industries, from automotive repair shops to food processing plants. Without a functioning air compressor, any number of machines and processes simply wouldn’t work. This is why it’s important to understand the parts that make up an air compressor, including reed valves. Let’s take a closer look at how these valves work and why they are so essential for any functioning air compressor.

What is a Reed Valve?

A reed valve is a small part used in many types of machinery, including air compressors. It’s made up of two thin metal plates that are held together by a flexible material such as rubber or plastic. The plates create an opening between them when the pressure is high enough, allowing the air to flow through. When the pressure drops, the plates close again and stop the flow of air.

The Functionality of Reed Valves

Reed valves play an essential role in keeping an air compressor running properly. They regulate the airflow into and out of the compressor by opening and closing at different times during its cycle. This helps ensure that the machine has enough pressure to perform its designated tasks without becoming overworked or damaged. In addition, reed valves also help reduce noise levels since they can be adjusted to control how much air passes through at once.

Benefits of Using Reed Valves

One major benefit to using reed valves is their durability—they can last for years with minimal maintenance required on your part! Additionally, they’re very cost-effective since they don’t require frequent replacement like some other types of valves do. Finally, reed valves offer great versatility since they can be adjusted depending on your particular needs and preferences for airflow rate or noise level reduction.

Cleaning the reed valves in an air compressor

Cleaning reed valves in an air compressor is an important part of maintaining the unit’s performance. In order to improve the efficiency and life span of your compressor, it is important to clean the reed valves regularly. Here are some steps you can follow to properly clean your reed valves for air compressor:

1. Remove the valve from the air compressor by unscrewing it from its housing. Use a socket wrench for this step if necessary.

2. Once removed, inspect both sides of the valve for any dirt or debris that could be blocking the flow of air through it. The intake side should be free from dust, dirt and other debris while the exhaust side should have no obstructions at all. If possible, use a can of compressed air to blow out any debris.

3. Once the valve is free from dust and debris, use a soft-bristled brush or toothbrush to gently scrub away any stubborn dirt and buildup on both sides of the valve. Be sure to pay special attention to the exhaust side as this is where most of the buildup will occur due to its constant exposure to hot air when in use.

4. When done cleaning, reassemble the valve back into its housing, making sure that it has been properly aligned before tightening it down with a socket wrench.

5. Test your compressor by running it for a few minutes and checking for proper operation. If all goes well, your reed valve should be clean and functioning properly.

By regularly cleaning your reed valves, you can ensure that your air compressor is running at its peak efficiency and performance. Proper maintenance and upkeep will also extend the life of your air compressor and keep it in top shape for many years to come. Additionally, by keeping your reed valves clean, you can help to prevent costly repairs down the line due to blocked or damaged valves.

Conclusion

Overall, reed valves are an invaluable component for any type of air compressor system—they provide efficient flow regulation while saving you money in maintenance costs and time spent replacing parts frequently! Not only that but they also help reduce noise levels which makes them even more beneficial for those who need to operate their compressors indoors or near populated areas where loud noises aren’t allowed or appreciated. With all these benefits combined, it’s easy to see why reed valves should be considered essential components for any functional air compressor system!